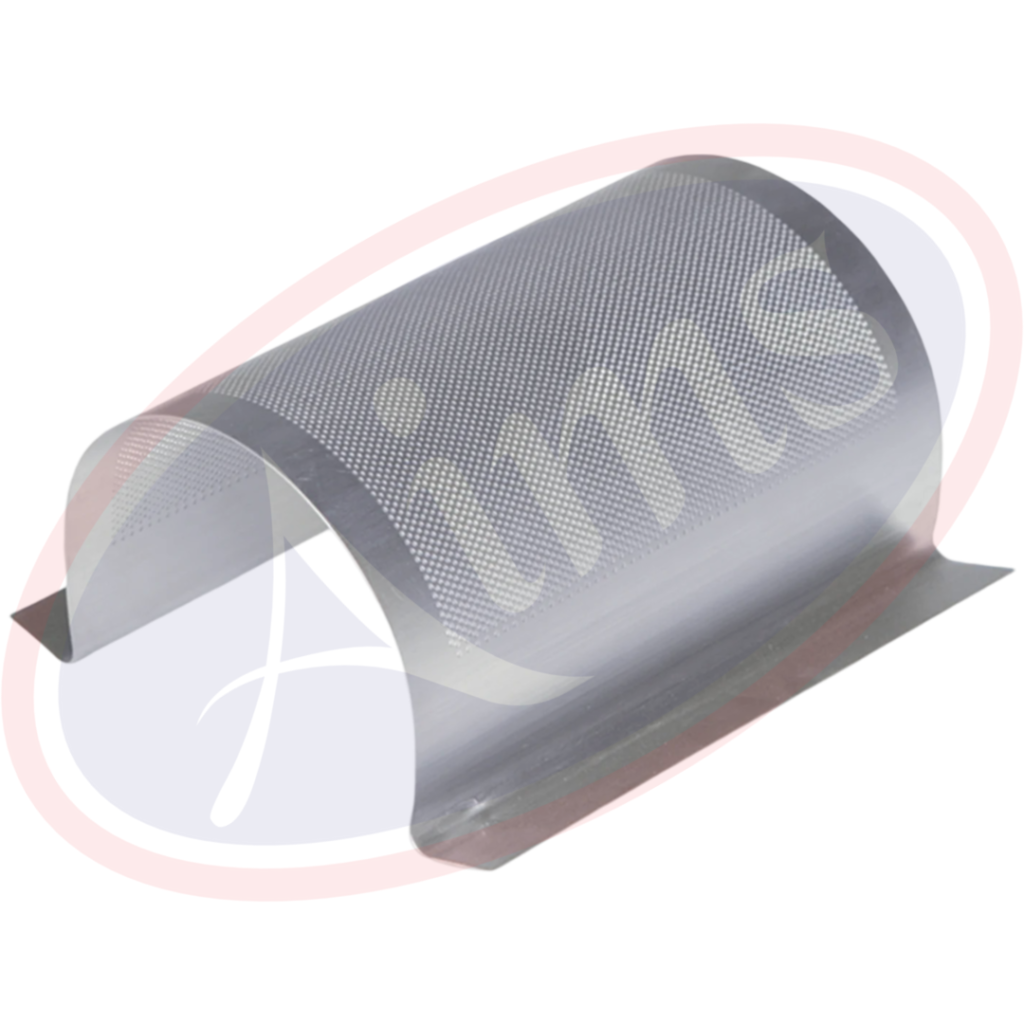

Oscillating Granulator Sieves

Overview

- Oscillating Granulator Is Important Part In The Granulation Process In Tablet Making Process Which Tablet Is Determined By The Virtue Of The Granules Used For Its Tablet Compression.

- Granulation Is A Mechanical Process In Which The Product Is Pressed Through A Sieve With A Specially Shaped Rotor-Arm To Obtain A Desired Particle Size. Oscillating Granulator Can Be Used For Wet And Dry Aspect Of The Granulation Process.

- Quality Of Granules Are Better Compared To Other Processing Machineries Like Multi Mill, Comminuting Mill Etc. For Proper Granulation Parameters Like Sieve Thick

Application

- Oscillating Granulator Sieves Are Useful In Dry Granulation, Wet Granulation, Screening, Crushing, Breaking

- Oscillating Granulator Sieves Has Application In Pharma, Food, Cosmetics, Confectionery, Fertilizers, Insecticides, Detergents, Electrolux Industries Etc.

- Oscillating Granulator Sieves Design Calibrated And Certified As Per International Standards.

- Oscillating Granulator Sieves Available In Various Sizes.

Technical Specifications

- Crevice Free, Lead-Free Sieves

- Crevice Free cGMP Design Quality

- Certified As Per International Standard

- Dimensions As Per Drawing / Sample

- Design Standards As Per ISO-9044, ASTM E-2016

- Material Of Construction : Stainless Steel 316-L

- Perforation Sizes Available From 0.5 mm To 15 mm