Capsule Filling Machine Ancillary Equipment

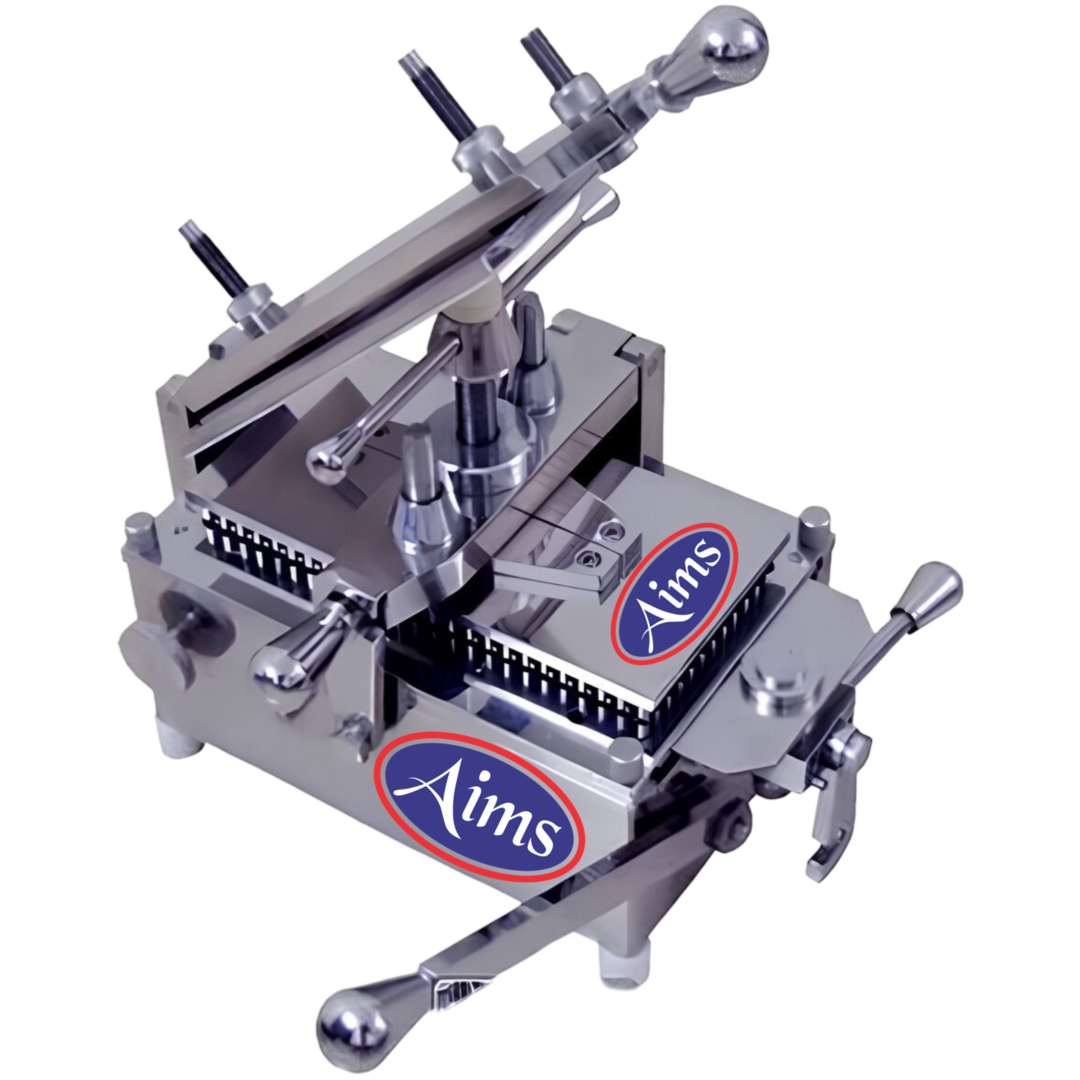

100 Holes Capsule Filling Machine

- 100 Holes Capsule Filling Machine Is Small Table Top Machine Suitable For Pilot Batch Productions.

- Machine Is Having 100 Holes With 10 X 10 Combinations Made In Stainless Steel Constructions Meeting GMP Requirements.

- Machine Can Fill Size 00 To Size 5 Capsules With Help Of Different Machines And Interchangeable Parts.

- Machine Assembly Has Been Done In Such A Way That It Can Be Easily Dismantle For Cleaning Operations.

- Though All The Operations Are Manual, The Machine Calls For Precision Machined Components And Assembled With Highly Skilled Personnel. Machine Having Wide Usage In R&D Laboratories, Research Institutions, Herbal & Nutraceutical Preparations, Unani & Ayurvedic Medicines Etc.

- Application : Filling Capsules With Powder, Pellets & Granules

- Cost-Effective : Save On Labor Costs And Minimize Errors With Automation.

- Durable Construction : Made From High-Quality Abs Plastic Material For Long-Lasting Performance.

- Easy To Clean : Designed For Quick And Easy Cleaning, Reducing Downtime.

- High Capacity : With 100 Holes, Fill Numerous Capsules Simultaneously, Saving Time.

- Suitability : Hard Gelatin, HPMC & Veg Capsules In 00, 0, 1, 2, 3, 4 & 5 Sizes

- Synonyms : 100 Holes Capsule Filler, Hand Capsule Filler, Nutritional Capsule Filler

- Versatile Application : Suitable For Pharmaceutical, Nutraceutical, And Herbal Products.

- Versions : Standard Model, GMP Model, Stainless Steel 316 Model

- Usage : Pharmaceutical, Nutritional, Biotech, Health Supplement, Food Product & Cosmetics

- User-Friendly Manual Operation : Easy To Use, Giving You Control Over Filling For Precise Results.

Salient Features

- cGMP Design Quality

- Certified As Per International Standards

- Dimensions As Per Drawing / Sample

- Change Parts For Each Capsule Size 00, 0, 1, 2, 3 Or 4 As Needed.

- Easy Handling Changes Of Size Plates.

- Ergonomic Features For Easy Cleaning And Avoid Of Contaminations.

- Lightweight Feeder Quickly Positions Capsules Into Filler.

- Manual Capsule Filler & Orienter Available In 100 Holes.

- Made From Stainless Steel For Reduced Static & Long-Life.

- Material Of Construction : Stainless Steel 316-L / HCHC Quality.

- Powder Tray Is Included To Minimize Powder Loss.

- 99% Orientation & 100% Capsule Separation.

300 Holes Capsule Filling Machine

- 300 Holes Capsule Filling Machine Is Small Table Top Machine Suitable For Pilot Batch Productions.

- Machine Is Having 300 Holes With 25 X 12 Combinations Made In Stainless Steel Constructions Meeting GMP Requirements.

- Machine Can Fill Size 00 To Size 5 Capsules With Help Of Different Machines And Interchangeable Parts.

- Machine Assembly Has Been Done In Such A Way That It Can Be Easily Dismantle For Cleaning Operations.

- Though All The Operations Are Manual, The Machine Calls For Precision Machined Components And Assembled With Highly Skilled Personnel. Machine Having Wide Usage In R&D Laboratories, Research Institutions, Herbal & Nutraceutical Preparations, Unani & Ayurvedic Medicines, Pilot Batch Productions.

- Automatic Capsule Loader & Manual Capsule Loader Available As An Optional Equipments Along With Capsule Filler To Speed Up The Productions.

- Application : Filling Capsules With Powder, Pellets & Granules

- Cost-Effective : Save On Labor Costs And Minimize Errors With Automation.

- Durable Construction : Made From High-Quality Abs Plastic Material For Long-Lasting Performance.

- Easy To Clean : Designed For Quick And Easy Cleaning, Reducing Downtime.

- High Capacity : With 300 Holes, Fill Numerous Capsules Simultaneously, Saving Time.

- Suitability : Hard Gelatin, HPMC & Veg Capsules In 00, 0, 1, 2, 3, 4 & 5 Sizes

- Synonyms : 300 Holes Capsule Filling Machine, 300 Holes Capsule Filler

- Versatile Application : Suitable For Pharmaceutical, Nutraceutical, And Herbal Products.

- Versions : Standard Model, GMP Model, Stainless Steel 316 Model

- Usage : Pharmaceutical, Nutritional, Biotech, Health Supplement, Food Product & Cosmetics

- User-Friendly Manual Operation : Easy To Use, Giving You Control Over Filling For Precise Results.

Salient Features

- cGMP Design Quality

- Certified As Per International Standards

- Dimensions As Per Drawing / Sample

- Change Parts For Each Capsule Size 00, 0, 1, 2, 3 Or 4 As Needed.

- Easy Handling Changes Of Size Plates.

- Ergonomic Features For Easy Cleaning And Avoid Of Contaminations.

- Lightweight Feeder Quickly Positions Capsules Into Filler.

- Manual Capsule Filler & Orienter Available In 100 Holes.

- Made From Stainless Steel For Reduced Static & Long-Life.

- Material Of Construction : Stainless Steel 316-L / HCHC Quality.

- Powder Tray Is Included To Minimize Powder Loss.

Technical Specifications

MODEL | AIMS – MCF – 300 |

Output Capacity Per Hour | Up To 6000 Capsules / Hour |

Capsule Combinations | Size 00, 0, 1, 2, 3, 4 & 5 |

Sequence Of Holes | 25 x 12 = 300 Holes |

Number Of Loading Tray | Three Loading Trays |

Net Weight (Kg) | 45 Kgs. Approx. |

Gross Weight (Kg) | 55 Kgs. Approx. |

Capsule Orienter | 300 Holes Manual (Stainless Steel) |

Overall Dimension (mm) | Length 400 X Width 350 X Height 450 |

Accessories | Loading Tray, Top Plate Powder Dispenser PTFE Scrapper, Brush & Small Tools |

Capsule Loader

- Capsule Loader Is Suitable For Loading Empty Capsules In The Loading Tray Of Manual Capsule Filling Machine To Enhance The Productivity

- This Equipment Is Ideal For Medium Scale Industries To Enhance The Output.

- Maximum Output Of Almost 90 Trays Per Hours I.E. 27,000 Capsules / Hour.

- Automatic Capsule Loading In The Tray And Stopping After Loading Is Complete.

- Simple Operation & Moderate Output Which Occupies Minimum Space.

- Machine Assembly Has Been Done In Such A Way That It Can Be Easily Dismantle For Cleaning Operations.

- Though All The Operations Are Manual, The Machine Calls For Precision Machined Components And Assembled With Highly Skilled Personnel.

- Machine Having Wide Usage In R&D Laboratories, Research Institutions.

Salient Features

- cGMP Design Quality

- Certified As Per International Standards

- Dimensions As Per Drawing / Sample

- Made With Stainless Steel For Reduced Static And Long-Life.

- Material Of Construction : Stainless Steel 316-L / HCHC

- Herbal & Nutraceutical Preparations, Unani & Ayurvedic Medicines Etc.

- Cost-Effective : Save On Labor Costs And Minimize Errors With Automation.

- Durable Construction : Made From High-Quality Stainless Steel Material For Long-Lasting Performance.

- Easy To Clean : Designed For Quick And Easy Cleaning, Reducing Downtime.

- Capacity : 90 Trays Per Hours I.E. 27,000 Capsules / Hour Capacity To Saving Time.

- Suitability : Hard Gelatin, HPMC & Veg Capsules In 00, 0, 1, 2, 3, 4 & 5 Sizes

- Versatile Application : Suitable For Pharmaceutical, Nutraceutical, And Herbal Products.

- Versions : Standard Model, GMP Model, Stainless Steel 316 Model

- Usage : Pharmaceutical, Nutritional, Biotech, Health Supplement, Food Product & Cosmetics

- User-Friendly Manual Operation : Easy To Use, Giving You Control Over Filling For Precise Results.

Technical Specifications

Output Capacity Per Hour | Up To 27,000 Capsules / Hour |

Noise Level (dB) | 80 dB Maximum |

Net Weight (Kg) | 125 Kgs. Approx. |

Gross Weight (Kg) | 150 Kgs. Approx. |

Overall Dimension (mm) | Length 750 X Width 450 X Height 900 |

Shipping Dimension (mm) | Length 1150 X Width 750 X Height 1100 |

Electric Motor (HP / kW / RPM) | 0.25 HP / 0.19 kW / 1440 RPM |

Electrical Power Supply | 230 Volts ± 10% / 50 Hz / 1 Φ Phase / A.C. Power Supply |

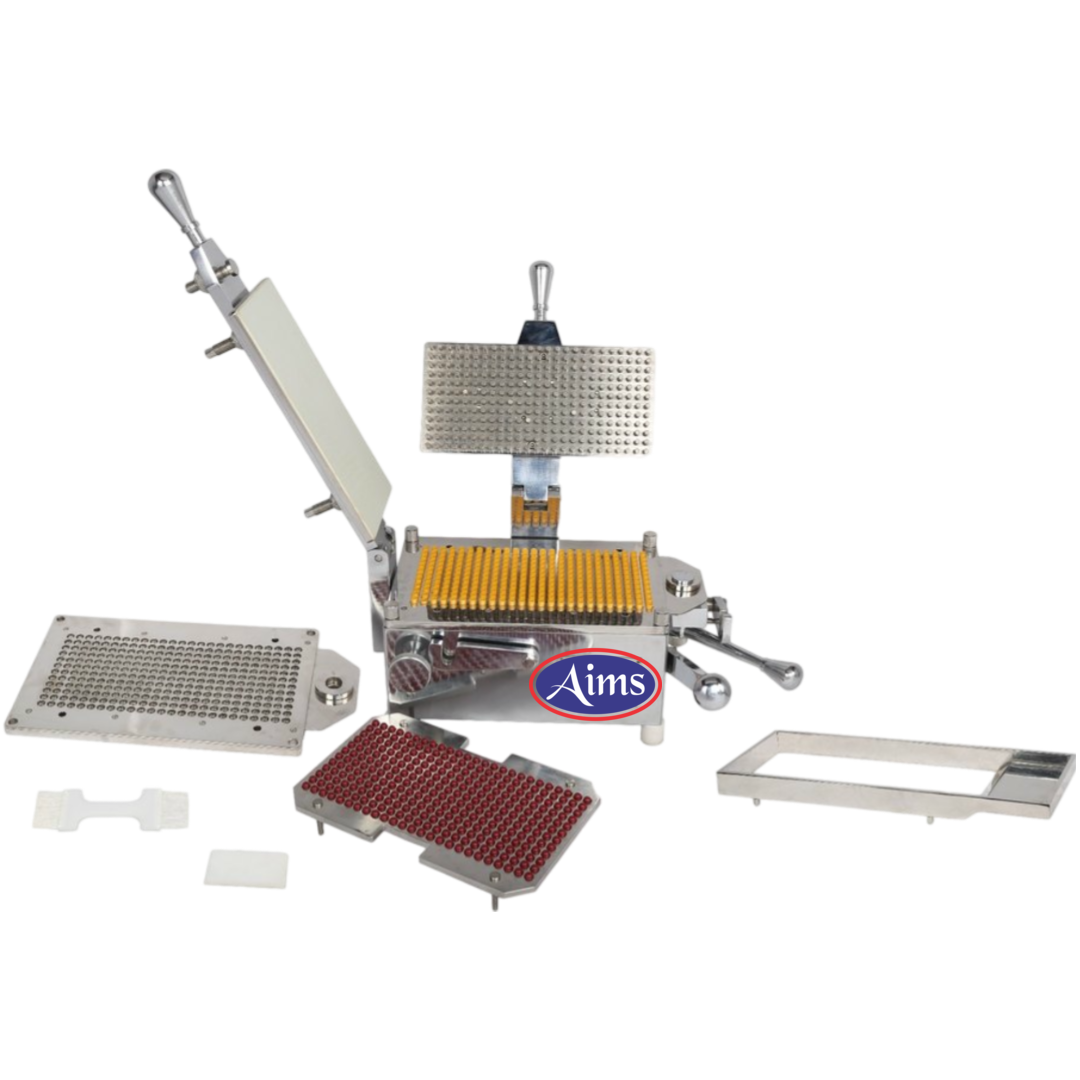

Manual Capsule Filling Machine (100 Holes / 300 Holes)

- Manual Capsule Filling Machine (100 Holes / 300 Holes) Is Small Table Top Machine Suitable For Pilot Batch Productions.

- 100 Holes Manual Capsule Filling Machine Is Having 100 Holes With 10 X 10 Combinations Made In Stainless Steel Constructions Meeting GMP Requirements.

- 300 Holes Manual Capsule Filling Machine Is Having 300 Holes With 25 X 12 Combinations Made In Stainless Steel Constructions Meeting GMP Requirements.

- Machine Can Fill Size 00 To Size 5 Capsules With Help Of Different Machines And Interchangeable Parts.

- Machine Assembly Has Been Done In Such A Way That It Can Be Easily Dismantle For Cleaning Operations.

- Though All The Operations Are Manual, The Machine Calls For Precision Machined Components And Assembled With Highly Skilled Personnel. Machine Having Wide Usage In R&D Laboratories, Research Institutions, Herbal & Nutraceutical Preparations, Unani & Ayurvedic Medicines Etc.

- Application : Filling Capsules With Powder, Pellets & Granules

- Cost-Effective : Save On Labor Costs And Minimize Errors With Automation.

- Durable Construction : Made From High-Quality Abs Plastic Material For Long-Lasting Performance.

- Easy To Clean : Designed For Quick And Easy Cleaning, Reducing Downtime.

- High Capacity : With 100 Holes & 300 Holes Fill Numerous Capsules Simultaneously, Saving Time.

- Suitability : Hard Gelatin, HPMC & Veg Capsules In 00, 0, 1, 2, 3, 4 & 5 Sizes

- Synonyms : 100 Holes & 300 Holes Capsule Filler, Hand Capsule Filler, Nutritional Capsule Filler

- Versatile Application : Suitable For Pharmaceutical, Nutraceutical, And Herbal Products.

- Versions : Standard Model, GMP Model, Stainless Steel 316 Model

- Usage : Pharmaceutical, Nutritional, Biotech, Health Supplement, Food Product & Cosmetics

- User-Friendly Manual Operation : Easy To Use, Giving You Control Over Filling For Precise Results.

Salient Features

- cGMP Design Quality

- Certified As Per International Standards

- Dimensions As Per Drawing / Sample

- Change Parts For Each Capsule Size 00, 0, 1, 2, 3 Or 4 As Needed.

- Easy Handling Changes Of Size Plates.

- Ergonomic Features For Easy Cleaning And Avoid Of Contaminations.

- Lightweight Feeder Quickly Positions Capsules Into Filler.

- Manual Capsule Filler & Orienter Available In 100 Holes & 300 Holes.

- Made From Stainless Steel For Reduced Static & Long-Life.

- Material Of Construction : Stainless Steel 316-L / HCHC Quality.

- Powder Tray Is Included To Minimize Powder Loss.

- 99% Orientation & 100% Capsule Separation.

Technical Specifications

MODEL | AIMS – MCF – 100 | AIMS – MCF – 300 |

Output Capacity Per Hour | Up To 3000 Capsules / Hour | Up To 6000 Capsules / Hour |

Capsule Combinations (Through Different Machines & Parts) | Size 00, 0, 1, 2, 3, 4 & 5 | Size 00, 0, 1, 2, 3, 4 & 5 |

Sequence Of Holes | 10 X 10 = 100 Holes | 25 x 12 = 300 Holes |

Number Of Loading Tray | One Loading Tray | Three Loading Trays |

Net Weight (Kg) | 25 Kgs. Approx. | 45 Kgs. Approx. |

Gross Weight (Kg) | 35 Kgs. Approx. | 55 Kgs. Approx. |

Capsule Orienter | 100 Holes Manual (Stainless Steel) | 300 Holes Manual (Stainless Steel) |

Overall Dimension (mm) | Length 350 X Width 300 X Height 400 | Length 400 X Width 350 X Height 450 |

Accessories | One Loading Tray, Top Plate Powder Dispenser, PTFE Scrapper, Brush & Small Tools | Three Loading Trays, Top Plate Powder Dispenser, PTFE Scrapper, Brush & Small Tools |